Multidisciplinary Team Experience

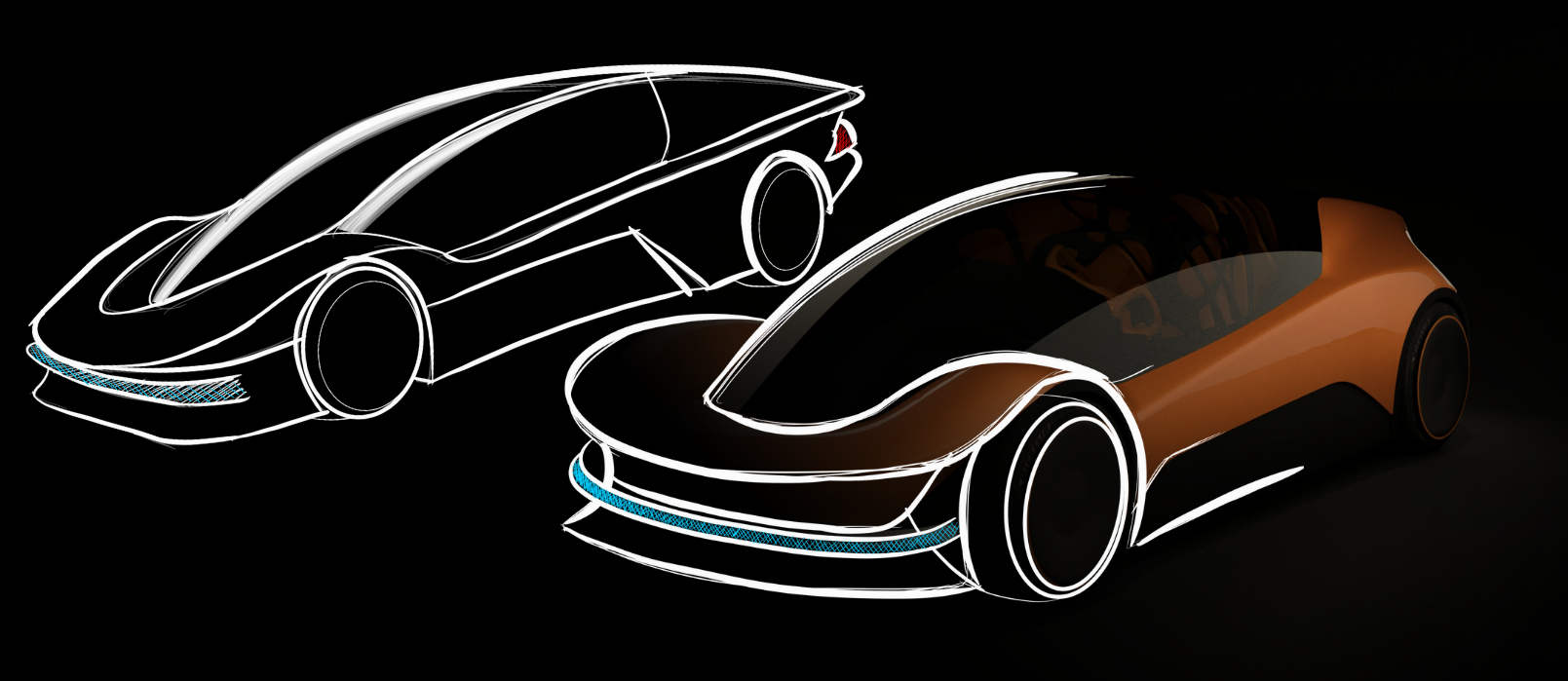

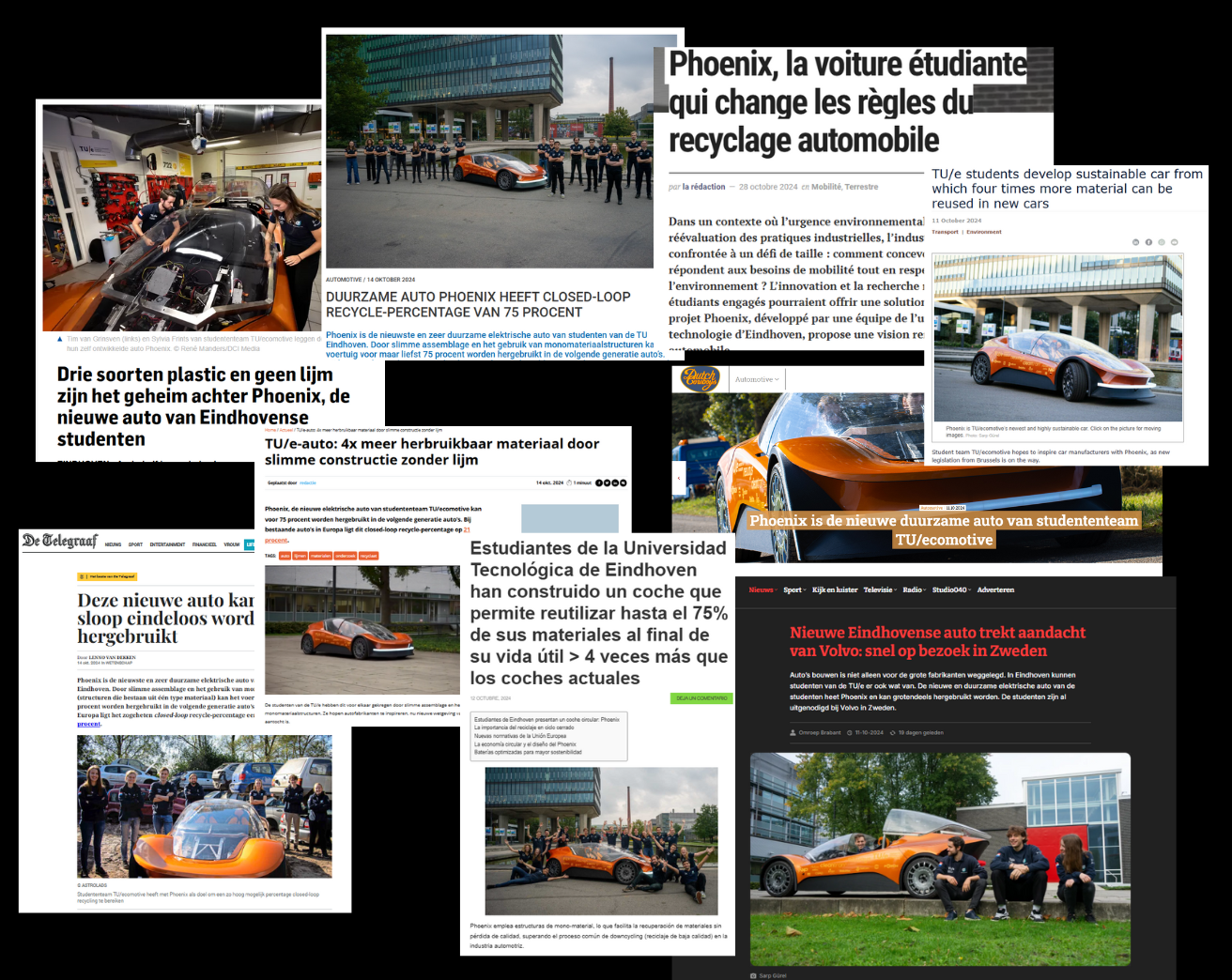

As part of the TU Ecomotive student team, I led exterior CAD design for a fully functional, sustainable car. It was crucial to work together with the thirty+ members of the team. From initial Blender concept sketches to detailed “design to fit” assemblies, I coordinated material selection, surface modeling, and mechanical integration. This experience sharpened my 3D‑CAD proficiency, design planning, and cross‑disciplinary collaboration—essential skills for realizing complex medical‑device housings and mechanisms.

As part of the TU Ecomotive student team, I led exterior CAD design for a fully functional, sustainable car. It was crucial to work together with the thirty+ members of the team. From initial Blender concept sketches to detailed “design to fit” assemblies, I coordinated material selection, surface modeling, and mechanical integration. This experience sharpened my 3D‑CAD proficiency, design planning, and cross‑disciplinary collaboration—essential skills for realizing complex medical‑device housings and mechanisms.

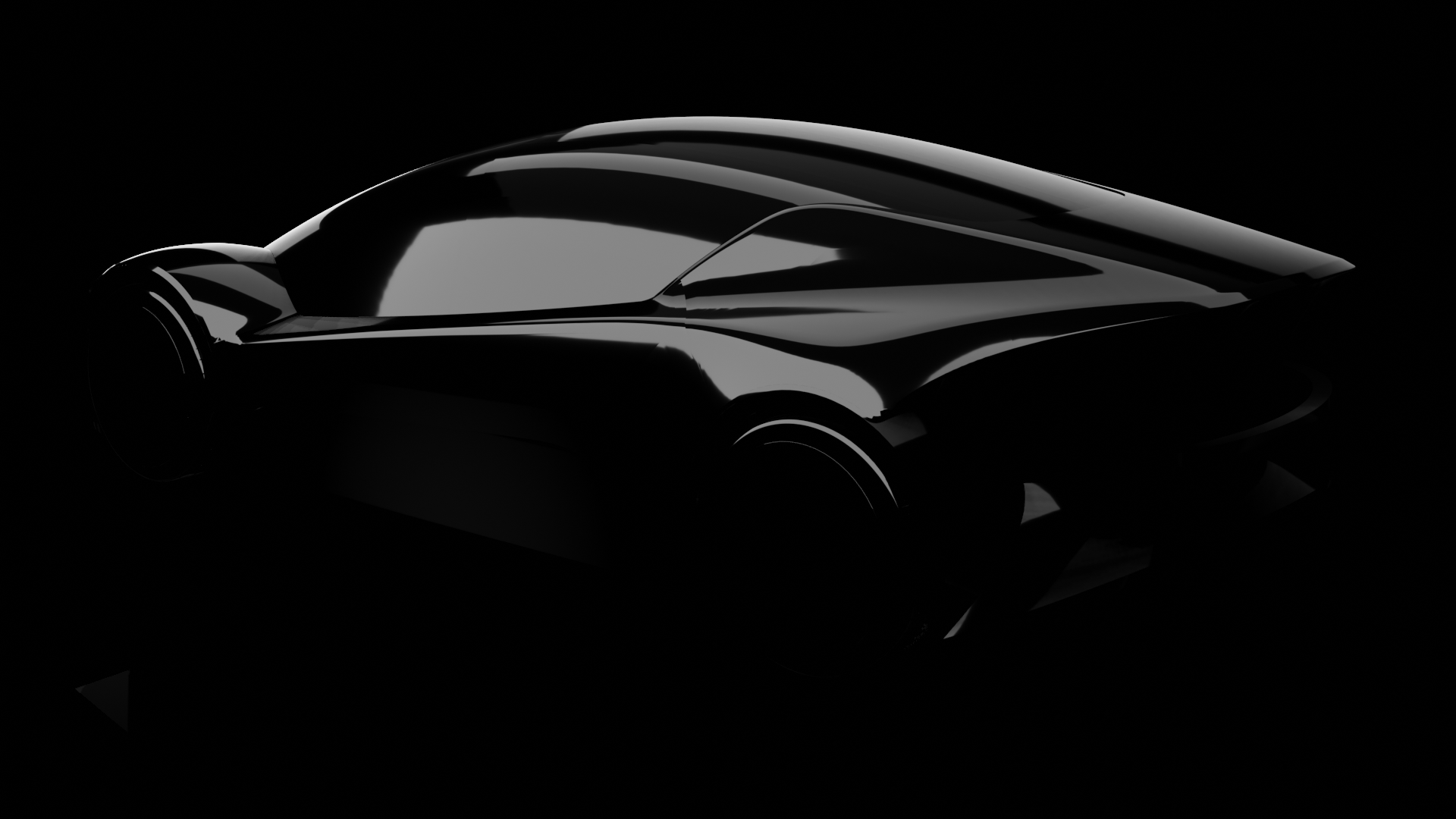

Teaser Shot Render

First Assembly

Process Sketches

International News

Completed Chassis

FBP Final Prototype

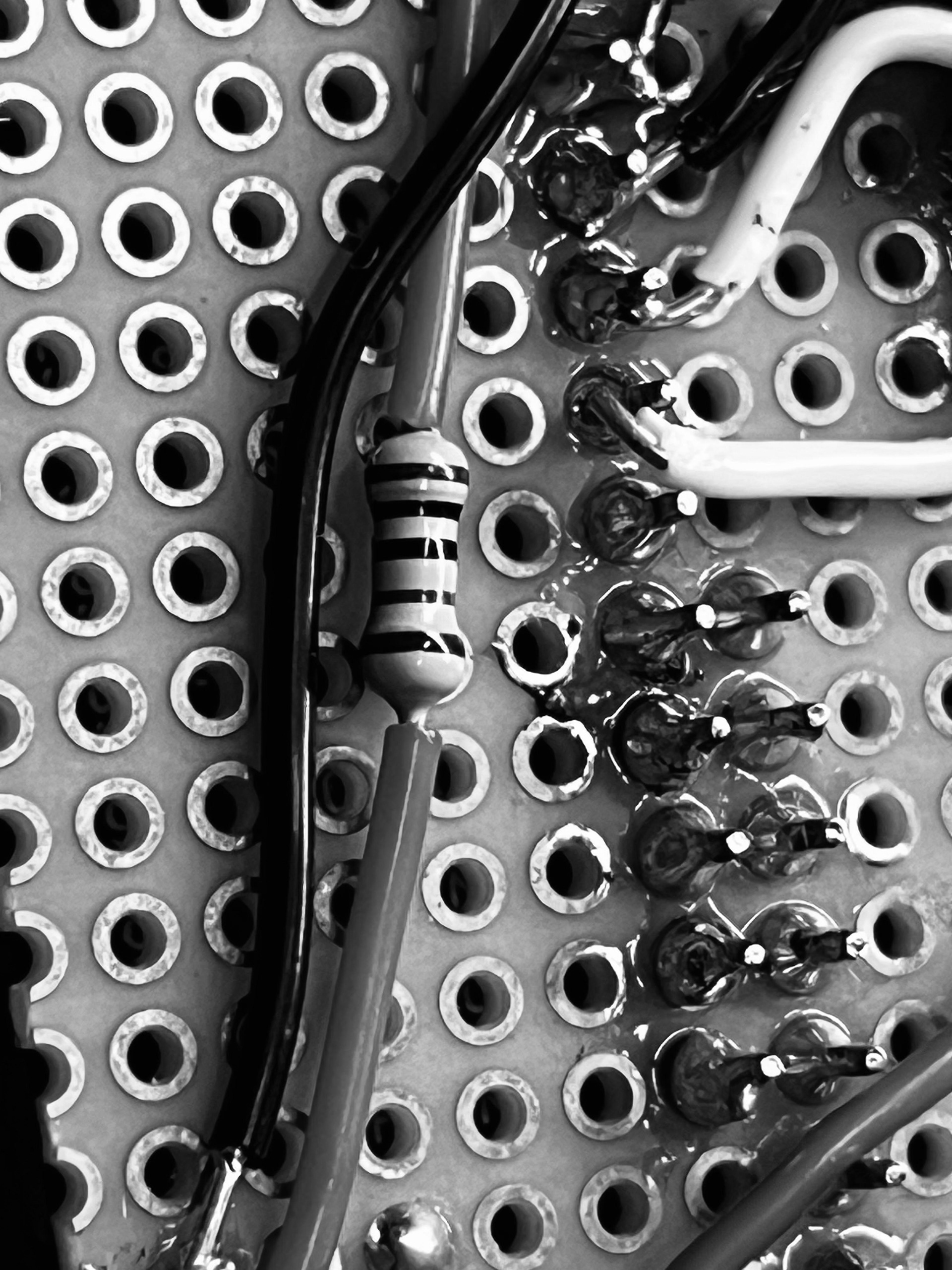

P2 Perfboard PCB

P3 Final Prototype

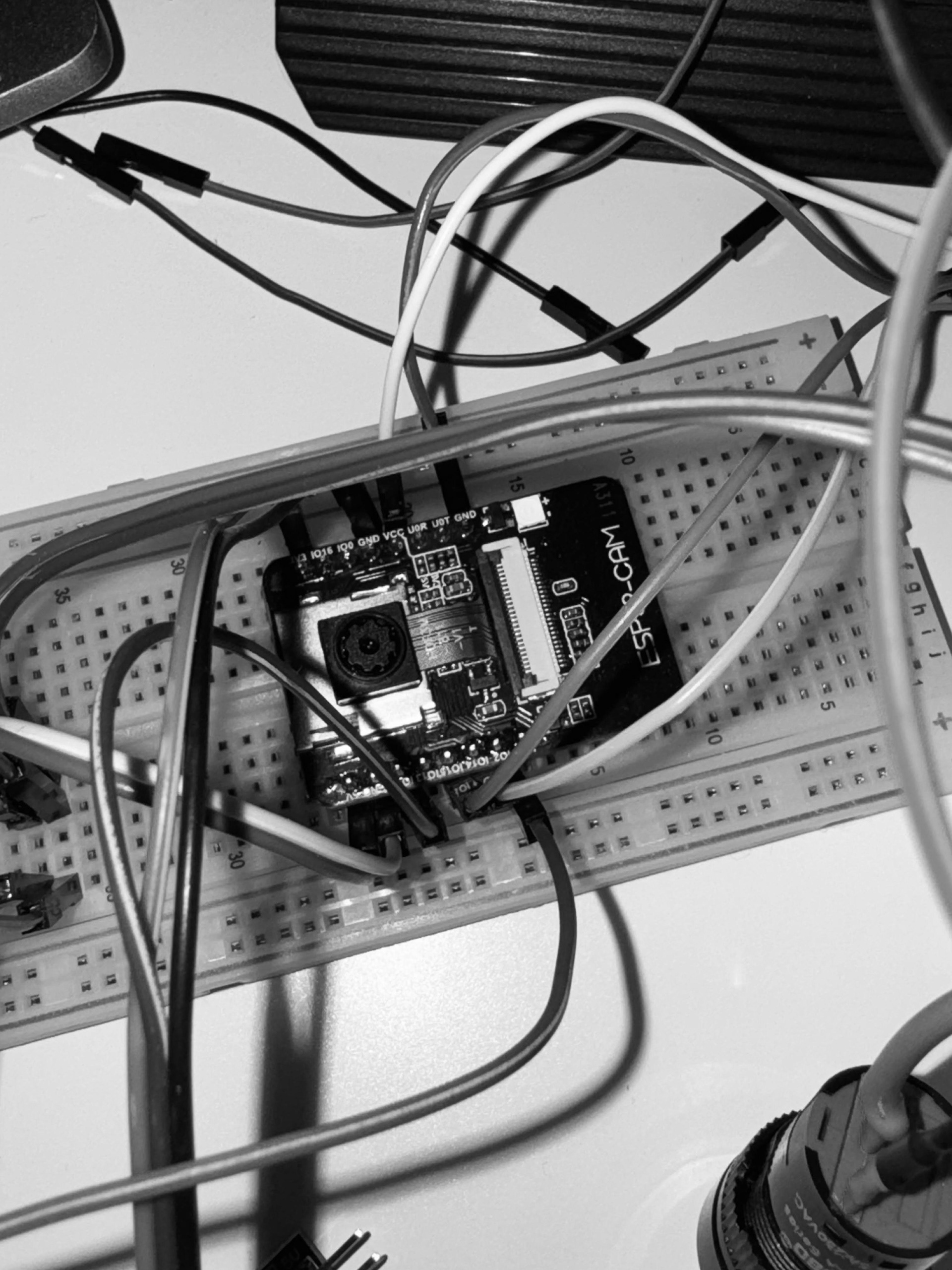

ESP32-CAM Breadboard

Embedded Systems & ElectronicsAcross all my ID projects, I incorporated Arduino, ESP modules, and a variety of sensors into my prototypes. Designing perfboard PCBs, soldering components, and programming microcontrollers taught me robust circuit design and firmware development. These hands‑on experiments laid the technical foundation for Oculo’s seamless electronics and reliable sensor interactions.

Branding & Visualization

Throughout my studies, I improved my brand identity within projects. During my exchange at NUS, I completed a branding course that enriched my branding skills. I created a new product for an existing company. I developed cohesive brand elements—logos, color palettes, packaging, and typography—and produced high‑quality renders to unify product identity. This refined my Creativity & Aesthetics expertise, ensuring every prototype communicates purpose through its unique branded identity.

Throughout my studies, I improved my brand identity within projects. During my exchange at NUS, I completed a branding course that enriched my branding skills. I created a new product for an existing company. I developed cohesive brand elements—logos, color palettes, packaging, and typography—and produced high‑quality renders to unify product identity. This refined my Creativity & Aesthetics expertise, ensuring every prototype communicates purpose through its unique branded identity.

Packaging Render

Playful Render

Color Options Render

Billboard Advertisement

Acrylic Sanding

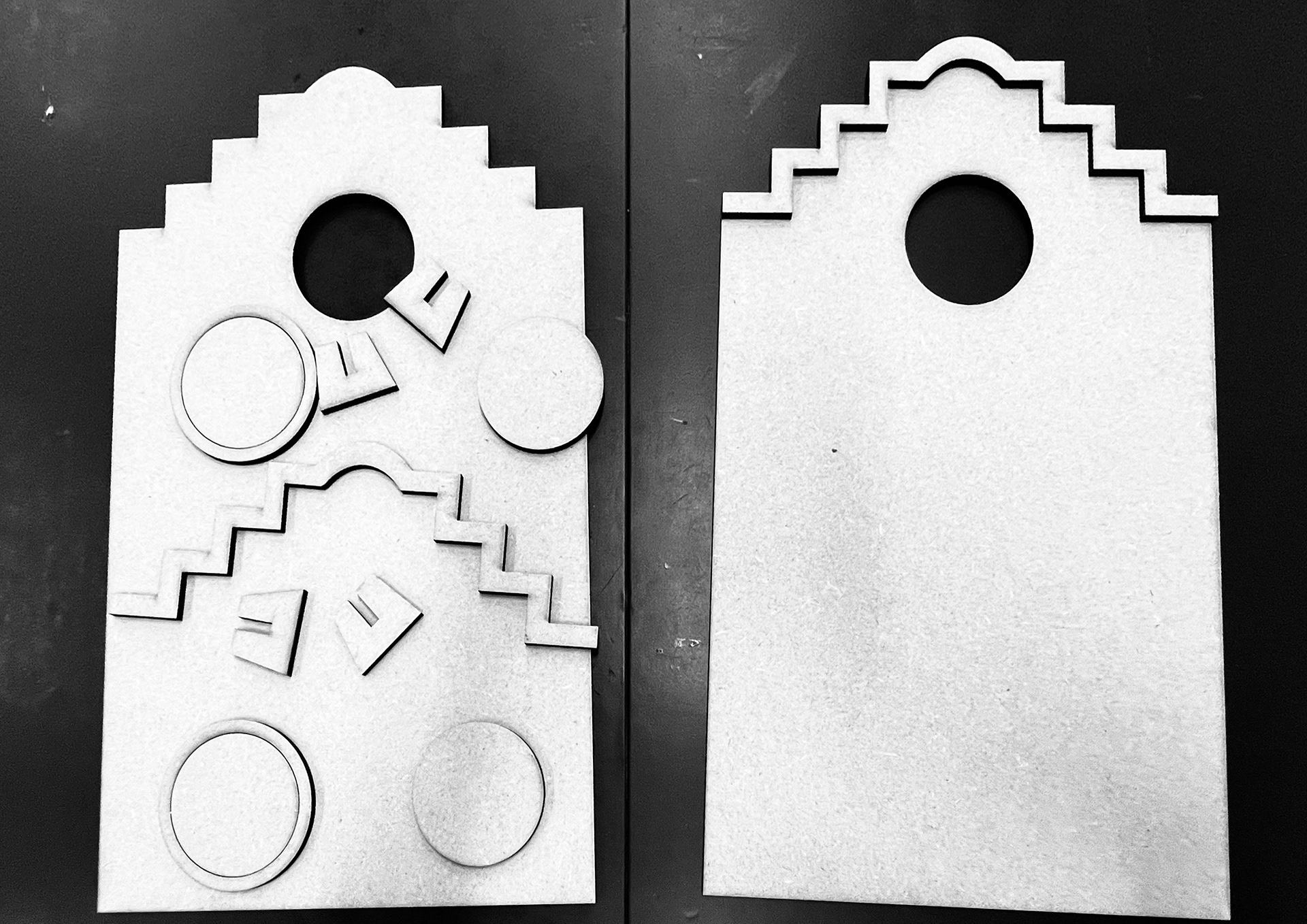

Laser Cut MDF

SLA Resin 3D Printing

FDM PLA 3D Printing

Wood Work (Demoday Stand)

Advanced Prototyping Techniques

To iterate rapidly, I employed wood‑working machines, laser cutters, PLA FDM, and SLA resin printing. Mastering additive‑manufacturing constraints—wall thickness, print orientation, fit tolerances, and slicing parameters—enabled me to produce precision parts that seamlessly assemble with electronics. This deepened my skills in Technology & Realization and prepared me for the high‑fidelity demands of medical‑device prototyping

To iterate rapidly, I employed wood‑working machines, laser cutters, PLA FDM, and SLA resin printing. Mastering additive‑manufacturing constraints—wall thickness, print orientation, fit tolerances, and slicing parameters—enabled me to produce precision parts that seamlessly assemble with electronics. This deepened my skills in Technology & Realization and prepared me for the high‑fidelity demands of medical‑device prototyping